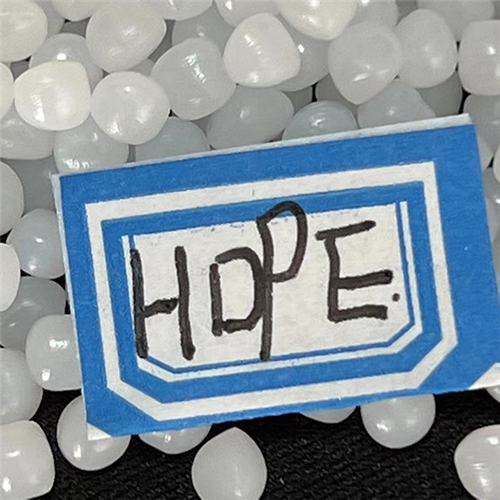

HDPE

HDPE

Formula:(C2h4)N

EINECS:618-339-3

Material:

High Density Polyethylene/HDPE

Usage:

General Plastics, Engineering Plastics, Specialty Plastics

PE

Polyethylene can

be divided into high density polyethylene, low density polyethylene and

linear low density polyethylene according to the polymerization method,

molecular weight and chain structure.

LOW DENSITY POLYETHYLENE (LDPE),

commonly known as high-pressure POLYETHYLENE, is mainly used in plastic

bags and agricultural film due to its LOW DENSITY and the softest

material.

HIGH DENSITY POLYETHYLENE (HDPE) is

commonly known as low pressure POLYETHYLENE. Compared with LDPE and

LLDPE, it has higher temperature resistance, oil resistance, steam

permeability resistance and environmental stress cracking resistance. In

addition, it has good electrical insulation, impact resistance and cold

resistance, which is mainly used in blow molding and injection molding

fields.

Linear Low Density Polyethylene (LLDPE) is

a copolymer of ethylene and a small amount of advanced olefin in the

presence of catalyst.LLDPE is similar to LDPE in appearance, with poor

transparency and good surface gloss. LLDPE has the advantages of low

temperature toughness, high modulus, bending resistance and stress

cracking resistance, and good impact strength at low temperature.

Application:

njection Moulding , Blow Moulding, Spin Dyeing, Casting, Extrusion Moulding, Blown Film, Foaming etc.

1. Fiber (Carpet,Textiles,Upholstery, etc.)

2. Film (shopping bags, casting film, multilayer film, etc.)

3. Blow Molding (Medical & Cosmetic container,Lubricant & Paint container, etc.)

4. Extrusion Molding (Sheet, Pipe, Wire & Cable, etc.)

5. Injection Molding(Automotive, Electronic, Construction, House wares, Furniture, Toys, etc.)